Are Your Parts Wearing Prematurely?

Catalog based, less expensive wear parts only appear to be saving you money.

Schedule a site visit to have our experts analyze your crushing equipment and discover ways our wear parts can increase your production.

Catalog based, less expensive wear parts only appear to be saving you money.

Quality castings that maintain their wear profiles for longer will maximize efficient energy consumption.

When your machines aren't running, you're losing money.

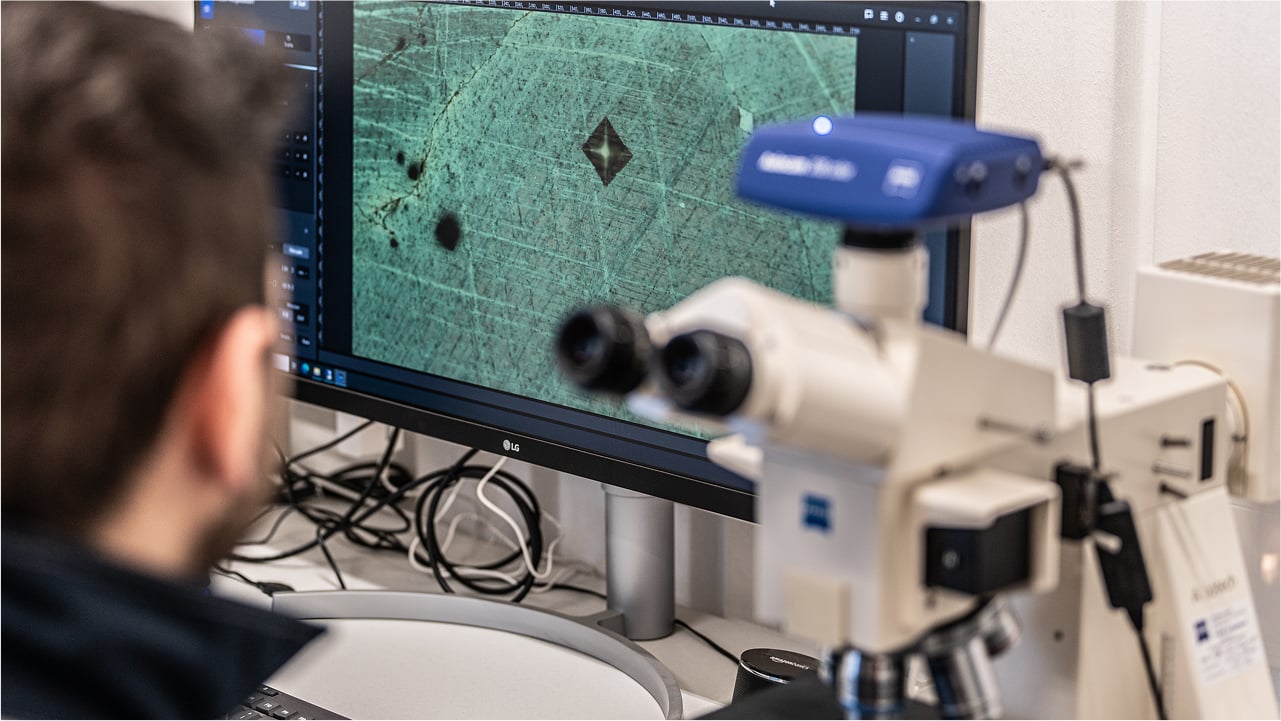

AMCAST’s Research and Development team has developed Patented alloys and Wear Resistant Inserts that deliver the best crusher wear parts performance in the industry.

We have developed new innovative manganese steel called MNXTM that combines exceptional wear resistance with high durability.

The winning property of this alloy is achieved by joining the typical Manganese Chrome alloy (MnCR18.2) toughness to a homogeneous and very fine dispersion of Chromium Carbide Hard Phases, with HV hardness values that are generally twice in comparison with typical manganese steel alloys.

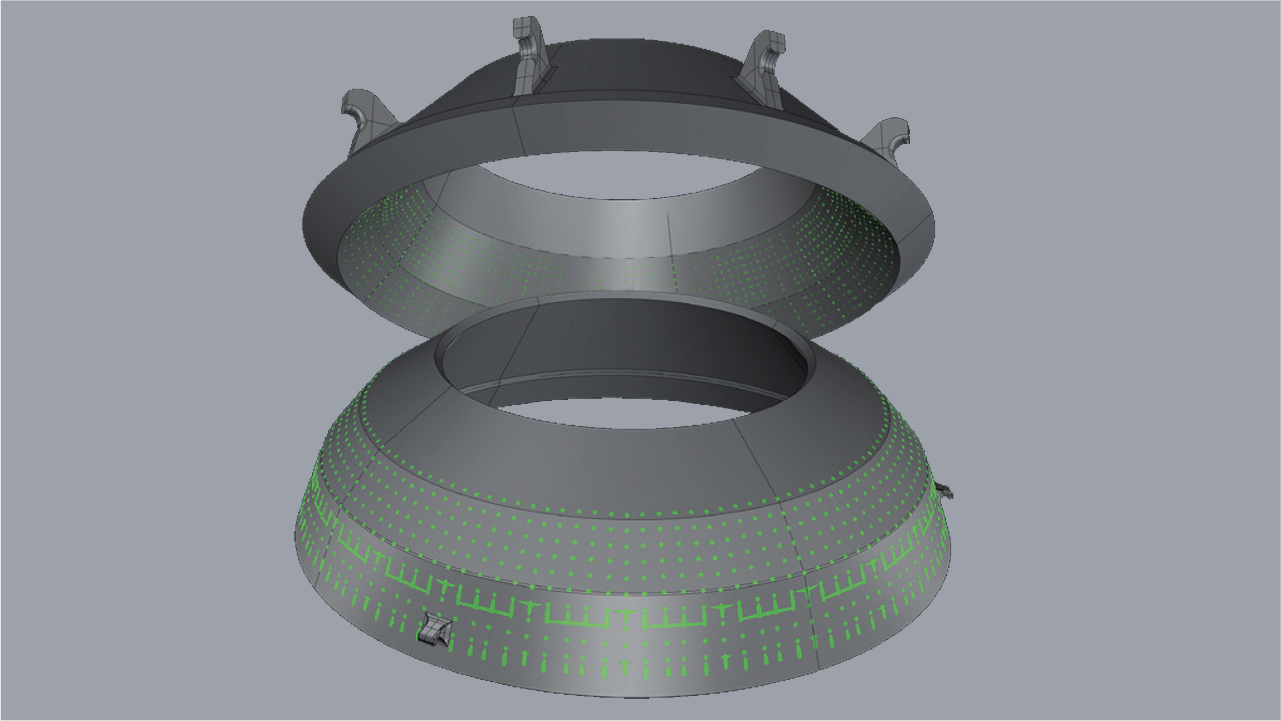

The GripPlusTM (GP) and GripPlusTM F-Mesh (GPF) inserts are made of a proprietary hard alloy, specifically designed to augment cone crusher liners. We tailor these hard inlays to match the customers needs according to site conditions, the results of profile scans performed by AMCAST specialists, and material samples. Through these methods, and collaboration with the on-site crushing and maintenance personnel, we determine where to apply the GP/ GPF inlays based on the liner's maximum wear zone.

The GPTM/ GPFTM inlays increase the hardness and durability of the surrounding manganese steel and are especially useful in both extreme applications and when there is not enough natural compression in the crushing zones for traditional manganese to work harden efficiently.

Speak with a product specialist.

Receive a custom quote for parts tailored specifically for your crushing operation.

Don't see what you need? Have our team of experts verify parts availability with a custom, on-site evaluation.

Machine downtime creates lost production and wasted man-hours. Cheaply made wear parts create an inferior product and keep you from outperforming your competition. AMCAST eliminates these problems by creating high-quality crusher wear parts using patented technologies developed through Material Science by our Research and Development Team.

With AMCAST's Crusher Wear parts, your production increases, you produce a better product, and your crushers maintain a more consistent power draw, maximizing energy consumption.

.png)