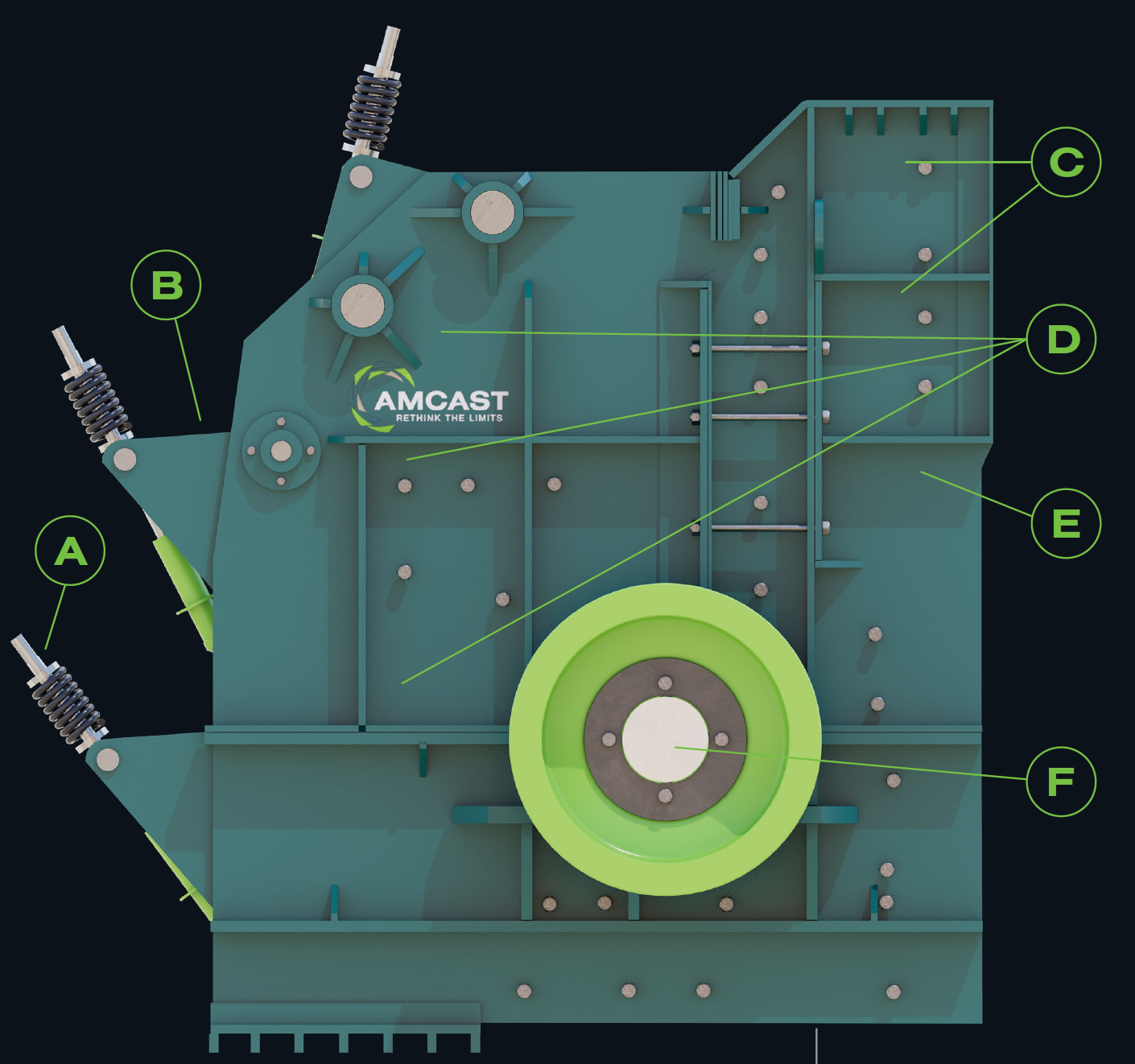

The GEO Crusher is Easy to Adjust

Hydraulically controlled feed inlet and apron systems means easier closed side setting adjustments and more crusher uptime.

For your crushing operations, get more options from our versatile and durable GEO series crushers. Designed by our experts in materials science and on-the-ground operations, these premium crushers get 90-95% efficiency and last longer, meaning you get more, no matter what you throw at it, time and time again.

This level of innovation is possible because AMCAST has been delivering custom premium crusher wear parts for almost 25 years. Our team is driven by cutting-edge material science, dedication to durability, and listening to, and working with, our customers. We know what works and we have excellent logistical operations to get your premium parts on-site fast, so your machines can work faster and longer.

Hydraulically controlled feed inlet and apron systems means easier closed side setting adjustments and more crusher uptime.

Simplified assembly and disassembly, for quicker maintenance and better uptime.

Get better impact even at lower speeds with our custom rotor and industry-leading wear parts.