Are you Using Multiple Crushers?

The RockyTM Transformer produces 85-100% useable sand in one pass with one machine.

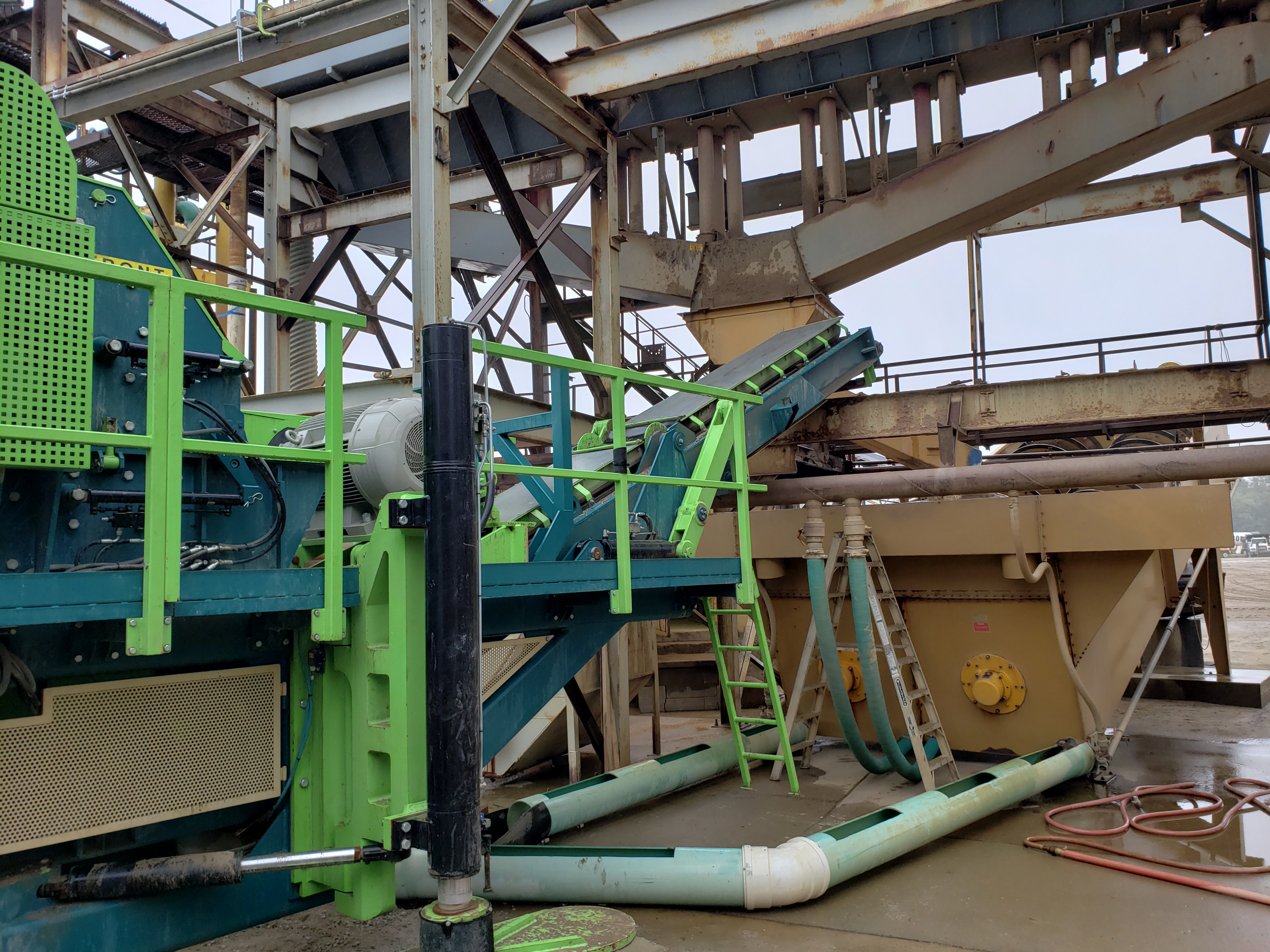

Schedule a site visit to have our experts analyze your crushing equipment and

discover ways the RockyTM can increase your sand production.

The RockyTM Transformer produces 85-100% useable sand in one pass with one machine.

The RockyTM uses rock on steel to produce a salable sand product with a near-perfect spherical grain structure.

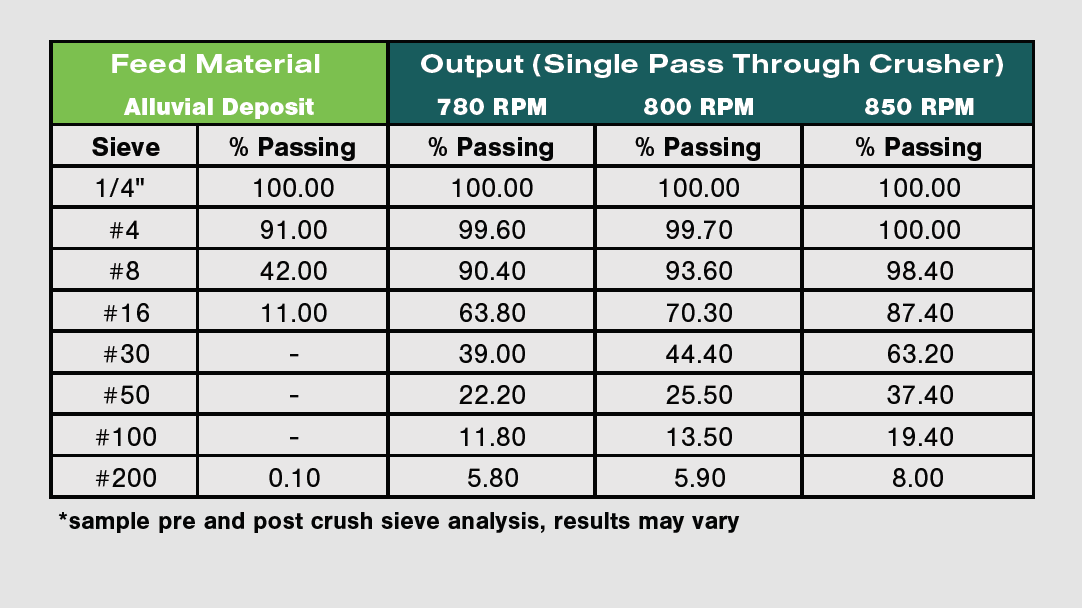

The RockyTM uses advanced automation for RPM and feed rate adjustments to control output gradations.

Producing high-quality sand from a variety of aggregate low-value aggregates. From cone crusher byproduct to virgin bank run river rock, the RockyTM produces a saleable sand product with near perfect spherical grain structure in just one pass. No grinding; No compression; Just 85-100% usable sand from a 100% impact crushing process.

Speak with a product specialist.

Receive a custom quote for parts tailored specifically for your crushing operation

Don't see what you need? Have our team of experts verify parts availability with a custom, on-site evaluation.

Machine downtime creates lost production and wasted man-hours. Cheaply made wear parts create an inferior product and keep you from outperforming your competition. AMCAST eliminates these problems by creating high-quality crusher wear parts using patented technologies developed through Material Science by our Research and Development Team.

With AMCAST's Crusher Wear parts, your production increases, you produce a better product, and your crushers maintain a more consistent power draw, maximizing energy consumption.

.png)