Getting to know AMCAST: Where it all began

Since the early 2000s, AMCAST has been on a road to revolutionizing the mining industry by stepping away from the beaten path and moving towards an...

1 min read

Tomaso Veneroso : Updated on February 13, 2024

AMCAST today announced the newest addition to FAR S.p.A’s hi-tech steel castings manufacturing facility; a prototype robotic automation. The head of the FAR’s robotic department, Alan Memmola, has driven this project to develop a custom, high performance

robotic system, offering increased precision in the general and fine dimensional grinding of cast

alloy wear parts.

robotic system, offering increased precision in the general and fine dimensional grinding of cast

alloy wear parts.

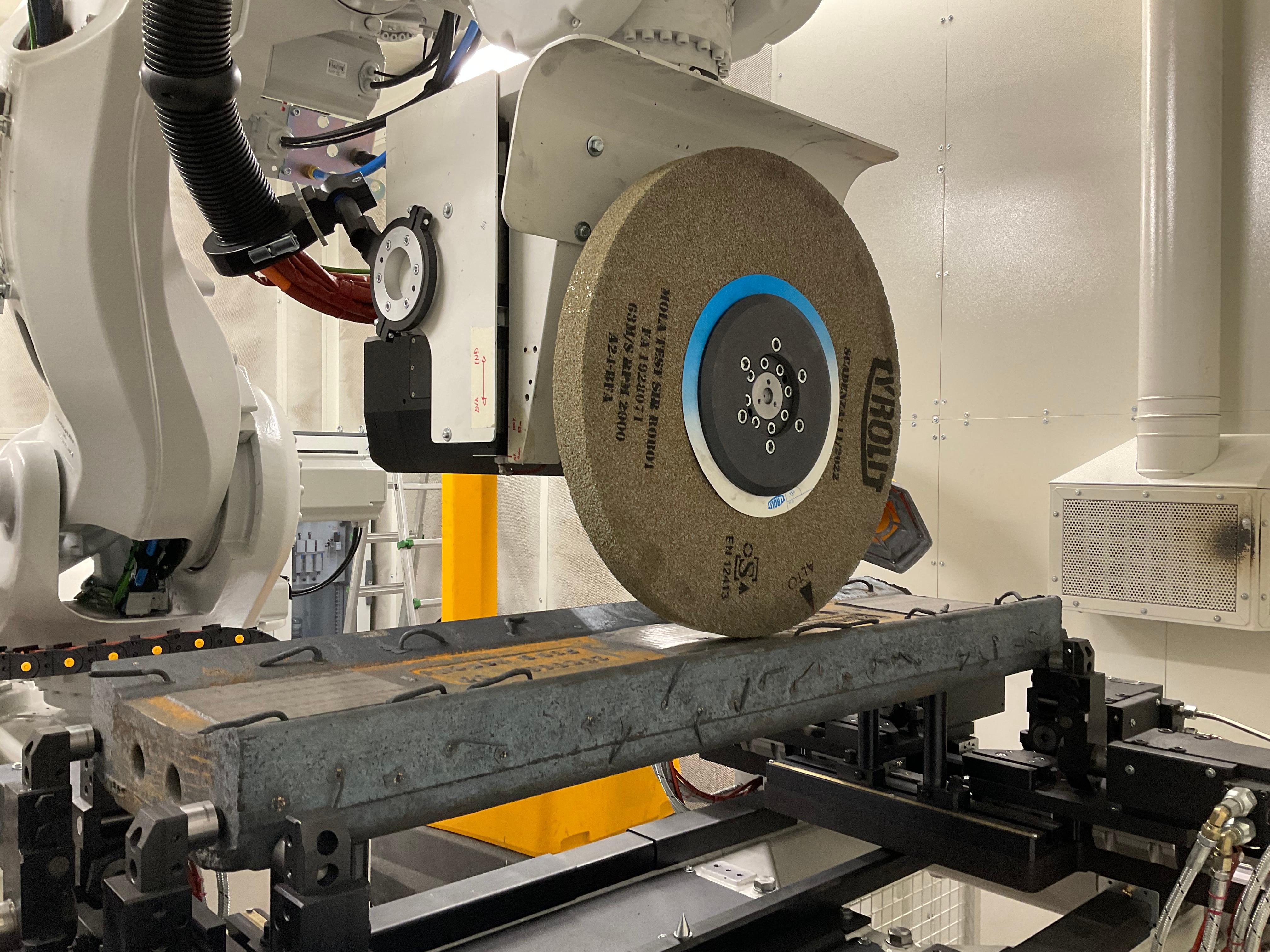

Pictured here is the latest in technology for steel casting manufacturing.

Pictured here is the latest in technology for steel casting manufacturing.

With a lifting capacity of 1760 lbs. and an overall reach of 65 in., this robotic automation has the ability of handling and manipulating heavy steel castings that would otherwise have to be lifted and positioned with overhead cranes.

This new technology effortlessly handles and maneuvers parts, scanning and relaying information back to an external data management system, where it can later be used in the proceeding steps of the manufacturing process. This automation system is comprised of specified programs that manage all lifting, rotating, loading, and positioning of the steel castings, particularly blow bars, onto the two stations used for grinding the parts six lateral faces.

In this video, see the prototype during the calibration phase as it’s put to the test grinding recently cast blow bars.

The prototype plant, boasts two machining cells consisting of two robotic arms each with 60kw spindles, 14 total tooling stations, measurement instruments, and four fully automatic workstations. This robotic system is particularly unique for its type of application in a steel manufacturing foundry.

Pictured here, the prototype robotic automation precisely grinds a cast blow bar, preparing it for final QC checks before being packaged for delivery

The AMCAST group is on a continuous quest for product excellence. By investing in research and development, material science, and the latest technologies, we are able to deliver previously unimaginable products and services to the mining and crushing industries.

Since the early 2000s, AMCAST has been on a road to revolutionizing the mining industry by stepping away from the beaten path and moving towards an...

This past week, the OSSGA held their Operations, Health and Safety Seminar. This one-day virtual event welcomed the industry to engage and discuss...

All around the world, the demand for sand is more intense than most would ever suspect. The importance of sand in our lives is not known by the...