AMCAST's CEO, Tomaso Veneroso, Speaks at This Years OSSGA Seminar

This past week, the OSSGA held their Operations, Health and Safety Seminar. This one-day virtual event welcomed the industry to engage and discuss...

1 min read

Tomaso Veneroso : Updated on February 13, 2024

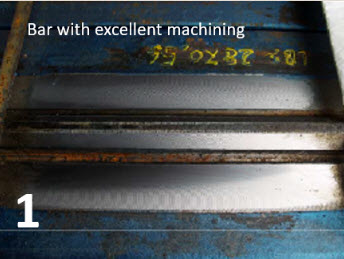

Image #1

An image of well-machined blow bars from AMCAST.

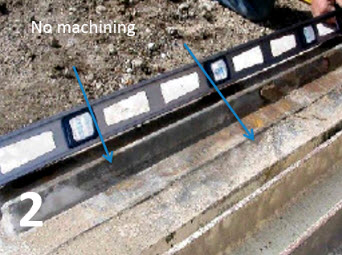

Image #2

This is a competitors blow bar. Notice that there is little or no machining left to the right of the ridge. In most cases, blow bars should be machined where they contact the rotor (or should at least be flat and straight). Notice the gaps under the straight edge showing light.

This does not support the blow bar properly and can lead to breakage!

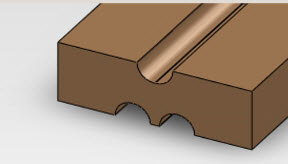

Grade “C” Blow Bar

Grade “C” Blow Bar

Poor shape (Average 4” thickness blow bar but with three deep grooves causing a poor rating)

Grade “C” Blow Bar

Grade “C” Blow Bar

Poor shape (Less than average thickness blow bar. 3.4” with a single deep groove causing a poor rating)

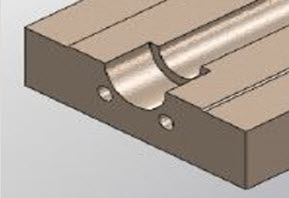

Grade “A” Blow Bar

Grade “A” Blow Bar

Excellent shape (Thicker than average thickness blow bar 4.5”, with positive noses to locate blow bar)

We have to be careful when we specify “Medium Chrome” and understand what family of alloys is to be used.

We have two alloy classifications for blow bars:

Note:

When customers ask for “medium chrome” always be aware that medium chrome is NOT halfway between Low chrome and High chrome, it is much closer to high chrome. So, medium chrome is not a general purpose blow bar and cannot do the work of both low & high chrome. It will do the work of high chrome but is at high risk of breakage when subjected to typical low chrome applications. Medium & High chrome alloys (white iron) have great wear properties, but you need to stay away from heavy duty applications such as large feed size (primary machine) or very high feed rates. WRI (ceramic) can be added to any of the alloys outlined above to solve this problem.

This past week, the OSSGA held their Operations, Health and Safety Seminar. This one-day virtual event welcomed the industry to engage and discuss...

There are many reasons why your impact crusher blow bars are breaking on a regular basis. We have compiled a list of the most common causes of blow...

.jpg)

Stone crushing can be classified into four stages depending on the degree to which the starting material is fragmented. These four stages are...